We use control components every day without a second thought – to start the car or turn on a light. The majority are simply switches – engaging and disengaging current according to a required logic.

Electrical control components based on switches are sufficient to control the acceleration and deceleration of engines, the programming of home appliances and the safe stopping and reversal of industrial motors. They are designed to keep both machinery and operators safe from shock or injury. Complex control systems can be built from just a handful of basic types.

Disconnecting switches

These combine a switch and fuse. To control a 3-phase motor a disconnecting switch consists of 3 knife-switches and 3 line fuses that can be switched manually with an external handle. Once blown by a surge of current their fuses have to be replaced.

Circuit breakers

Unlike fuses, breakers open non-destructively if current exceeds a safe value, so can be reset once the problem has been corrected.

The simplest type is an MCB (miniature circuit breaker) – an electromagnetically operated switch inserted into the live side of the circuit. An RCD (residual current device) is similar in appearance but connects to both live and neutral and employs a variety of means to indicate the nature of any fault.

Industry employs even more elaborate forms, often embedded in transformers and relays. For more information see https://www.diydoctor.org.uk/projects/fuses.htm, or view a selection here http://www.osmelectrical.com/.

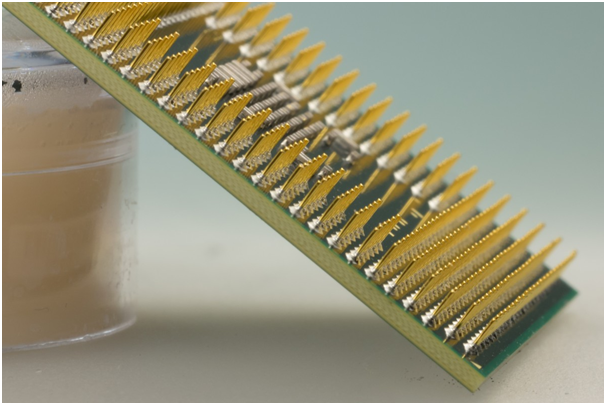

Cam switches

Often used to control hoists or machining tools, these combine groups of fixed and moveable contacts that operate circuits in a specific sequence as the contacts are rotated.

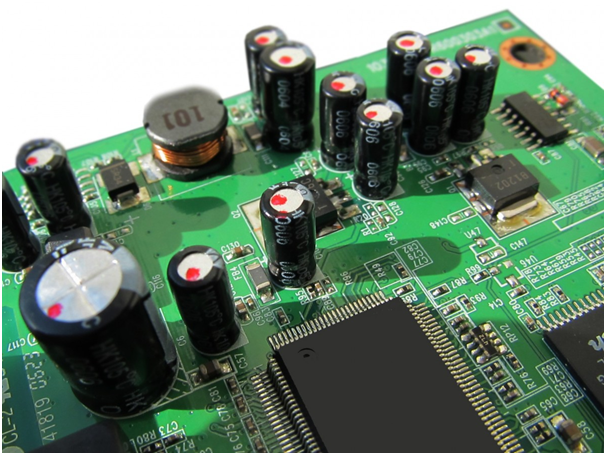

Control relays

In these, a set of contacts is opened or closed by a separately powered electromagnetic coil. Sometimes these are fitted to isolate users from a higher powered circuit (in which case a “magnetic contactor” will be used) but they can be linked to time switches, sensors or programmed logic controllers.

Thermal relays

These are similar in function but are triggered by a calibrated heating element. This mechanism introduces a small time delay compared to electromagnetic relays.

Limit switches

Mechanical limiters open or close circuits with a snap-action when a mechanical part reaches a particular operating position. Other types of limiter can be triggered by pressure, fluid levels, temperatures, or directions of acceleration, providing many means to guarantee safe operation and automate production lines.