‘Dilute’ and ‘dense’ refer to the relative proportions of air and transported material; therefore, a dilute phase conveyor moves a relatively high amount of air to transport a given quantity of material – typically 5,000’-8,000’ per minute. At these speeds material is kept airborne and continuous steady throughput is maximised. In contrast, dense phase systems tumble material through the conveyor gently with typical velocities from 400’-2,000’ per minute.

Dilute conveying is less suitable for materials that are abrasive, fragile, or prone to segregation; however, about three-quarters of conveyors use the dilute approach, and dilute phase conveying continues to experience strong worldwide year-on-year growth.

Advantages and disadvantages

Mixtures may be prone to separate under dilute conditions, hence dense phase is often selected for processes such as conveying blended ingredients during food preparation, either to the next process phase or to packaging.

Theoretically the slower operation of dense phase provides an energy saving, providing all components of the system are well matched; however, there is often a bigger initial investment because maintaining optimum pressure drop across the system is more critical and requires efficient gas-tight valves to keep material moving steadily. For the same reason, dense phase is less suitable for longer runs.

Dilute systems are easier to install, route and maintain, providing a steadier and more continuous throughput.

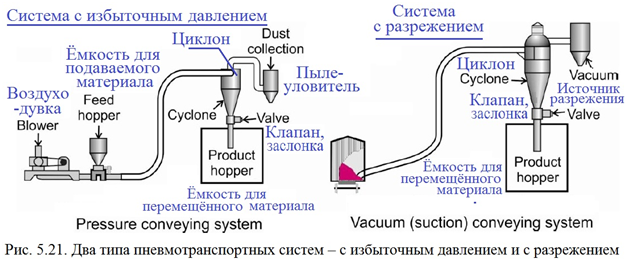

Vacuum or positive pressure

Either type of flow can be driven by blowers upstream of the material intake or vacuum pumps downstream of the discharge points. Vacuum conveying compounds some of the drawbacks of dense phase, such as shorter runs and critical sealing; therefore, dilute vacuum conveying is more common. In either case, the design of a vacuum conveyor requires the assistance of a specialist such as http://www.aptech.uk.com/pneumatic-conveying/vacuum-conveying/.

In vacuum conveyors material can be discharged in batches through butterfly or slide gate valves, or continuously using rotary airlocks. Vacuum-driven conveyors make it easier to pull from multiple sources and deliver to a single destination, and vice versa with positive pressure. Airlocks are located at the inlet of a pressure driven system and at the discharge point of a vacuum one. Using vacuum pumps makes it easier to eliminate all leakage and maintain a clean environment, which is a very common reason for selecting these systems.

Hybrid vacuum/pressure dilute phase systems are also possible that combine the advantages of both pressure and vacuum systems.