One of the most versatile surface treatments available for metals is thermal plasma spraying. There are a number of methods to achieve it, but essentially a plasma spray consists of molten particles projected on to the substrate at high velocity. Despite the name, it can be a “cold process” in that the substrate temperature can be controlled, which avoids any risk of distortion.

The surface coatings are typically dense, strong and durable and with the right choice of materials vastly extend the properties of the original uncoated artefact.

How a Thermal Plasma Spray Is Created

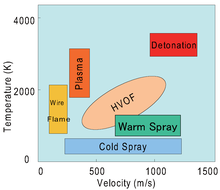

There are several technologies available to deliver a thermal plasma spray. These include electric arc spraying, wire spraying and using high-velocity oxygen fuel (HVOF) or high-velocity air fuel (HVAF). The choice of technique provides even more control over the finished result and its micro-properties.

However, the basic principle is the same. The coating material begins as a fine powder that is injected into a high-temperature flame which heats and ejects it very rapidly. Because of the fine size of these particles they then cool extremely rapidly when they impact the substrate. This rapidity, combined with the force of delivery, serves to create a very firm and durable bond. After building up layers of material, the result can be harder and firmer than coatings of the same material deposited by any other surface treatment.

A typical spray gun consists of a copper anode and tungsten cathode. Both are water-cooled. Hydrogen or an inert gas flows from the cathode through a narrow gate in the anode, ionised into plasma by an electrical arc between them. Powdered coating is introduced by an injector near the anode. See the diagram here: https://www.researchgate.net/figure/The-background-of-Atmospheric-Plasma-Spraying-process-23-Rys-1-Podstawy_fig8_282977751.

In some methods the arc is confined within the gun, and in others allowed to extend to the substrate. Operations can be confined in a protective booth, but on-site work is also possible with appropriate equipment.

The Coatings

Even materials with very high melting points, like ceramics and tungsten, can be sprayed. Typical coatings include chrome oxide, yttria stabilised zirconia, molybdenum, alumina and alumina-polyester composites. For more details and additional coatings, see https://www.poeton.co.uk/plasma-coatings/.

In the majority of cases, the surfaces will be prepared by blasting to create the ideal coarse surface for bonding. However, other processes are available to create the same effect.