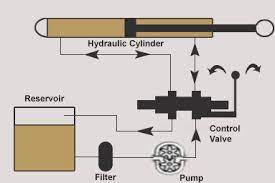

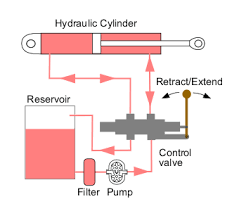

A hydraulic system is a mechanism that uses pressurised fluid to perform mechanical tasks. Its essential components include pumps, valves, piping, accessories, and fluid-controlling elements.

The hydraulic system enables a vehicle or machine to move and transfer power.

Hydraulic systems generally use an electrical or engine-driven pump as the primary pressure source. In some cases, the system may also have an electric pump that provides a backup pressure source if the leading pump fails. Using multiple pressure sources helps ensure the system’s integrity if one or more components fail. For Hydraulic Power Unit products, go to hydraproducts.co.uk/Hydraulic-Power-Units/Standard-Power-Units

When a pressure relief valve is in place, the pressurised fluid can drain back into the reservoir. Depending on the type of pump, the pressure relief valve can be found on the inlet or outlet side of the pump. Typically, the relief valve is the first control valve in the system.

Pressure relief valves are essential because they prevent the system from reaching an unacceptably high pressure. They are also helpful in high-low pump circuits to avoid the acceleration of the load. Other pressure valves include overflow valves, sequence valves, and pressure-reducing valves.

A hydraulic system contains three major parts: the pump, the fluid power pack, and the reservoir. Each component plays a different role in the overall design. For example, the hydraulic pump is used to push the fluid from the pool to the pump. During the process, the pump creates a partial vacuum at the inlet.

As the pump starts to push, the pressure in the fluid rises. This pressure is measured in pounds per square inch (psi). Often, psi units are used for measuring hydraulic system components.

If the pressure is too low, it will damage the hydraulic cylinder. Similarly, the pump will damage the transmission shaft or the cylinder if the pressure is too high. And when the fluid is frozen, the system will shut down.

Typically, hydraulic hoses follow the path of least resistance. But this route can be changed depending on the hydraulic system’s design.

The hydraulic valves in the system control pressures and speeds. This is a crucial part of the operation of a hydraulic system. The valves allow the operator to dictate the direction and flow of the fluid. Flow valves also regulate the flow of oil in the hydraulic circuit.

The power input segment comprises the prime mover, which transfers mechanical energy to the hydraulic power pack. The power pack can be piped to the actuators for rotational or linear motion.